Robert Waddell

(4 Jul 1883 – 19 Jan 1952)

The photograph on the right shows Robert in uncharacteristically jaunty pose, but he had dourer aspects to his personality, as we shall see. In fact, like most of us, he was most probably a quirky mix of morose and merry. Aunt Jane recollects that he could be very good fun on social occasions.

The narrative that follows is transcribed from Alexander (Sandy) Waddell's invaluable summary in his biographical document WADDELL LINE WHO'S WHO.

Summary transcript

Born 4 July 1883, the second child of James Waddell and Margaret (née Little), at Glasgow. His parents would have been on leave from Singapore where his father represented the affairs of the shipping company Nederlandsch-Indische Stoomvaat Maatschappij which despite its name was English owned. With his elder brother Peter, born 18 December 1881 at Singapore, the family returned there. Sisters Mary (Mollie) born at Singapore in 1885, Helen Halcro 1887 (who died in infancy) and Margaret (Meg) born 1889 at Surabaya, Java, completed the family.

The shipping line ceased its operations late in 1891, and must have repatriated the family to Glasgow by January 1892 when Robert would have been 8½ years old. All of them must have suffered from malaria at some time, and he carried a malignant form which recurred at extending intervals through his life. He was also short-sighted and in need of skilled optical attention.

In April his father was offered a post by the Royal Dutch Oil Company as General Manager of their Petroleum and Kerosene enterprise at Pangkalan Brandan, Sumatra. He accepted the offer and, leaving the family in Glasgow, had taken over responsibility by 24 June 1892. It was left to their mother to arrange for their schooling. The boys attended variously Allan Glenns School (a spartan contrast to the way of life in the East) and Kelvinside Academy. In the junior school of the latter, H.M. Stanley's Through the Dark Continent was awarded to him for being 1st in both Latin and Scripture, 2nd in English and 3rd in Drawing during the session 1894-1895. There is little evidence that this volume was ever read. It has now lost the binding from the spine.

His father's service in Sumatra was not protracted. For reasons already recorded he resigned his appointment in Sumatra 15 March 1893 and returned home. There was no great affluence and no record exists whether he received any pension from his previous service or if he found later employment. Furthermore he was suffering increasing incapacity resulting from an injury to his back, said to have been sustained when surveying a ship in dry dock, possibly at Singapore. Invalidism tended to make him a recluse and the house in Dowanhill depressing. Robert later came to know the family of Rev. Robert Primrose and thus met a wider circle of friends.

Peter, his elder brother, was of a classical bent, passing via Edinburgh1 University to Balliol College, Oxford. By contrast Robert was entered as a student apprentice in the Dennys Shipyard where he served through all the departments (as opposed to a trade apprentice) and studying in the evenings at the Glasgow Technical College, later to become the University of Strathclyde, to gain his diploma in Naval Architecture. By preference he wished to be involved with yacht design, but generally opportunities were at a low ebb and so decided to emigrate to America around 19082. There he first found employment on the Eastern seaboard where wooden hulled sailing ships were still being built. He must have heard of more rewarding employ if he went further West and so made his way to Seattle, then rapidly expanding, where he was employed by the Washington Iron Company3, a yard building steel hulled ships and naval destroyers besides winches and machinery for the logging trade4. Here he was able to utilise his training to the full and in time becoming responsible for the builders during seagoing acceptance trials. The measured mile was just south of the Canadian base at Esquimault on Vancouver Island.

His fiancée, Frances Hannah Findlay, joined him in Seattle where they were married at Trinity Parish Church 20 April 1912 by the Rector Herbert H Gowen in the presence of Miriam and Hilda Little as witnesses. They were cousins on his mother's side, being daughters of Matthew Little and his second wife Harriet Lawrence. It was a long way from Hampstead whither Matthew had retired from Singapore in 1877. Maybe they were on a world tour. Arthur Nation (an intended godfather to the compiler) was best man.

Their family ultimately comprised Walter Wardlaw b. 16 February 1913 at Liverpool5, Robert (Robin) Erskine b. 23 September6 1916 at Seattle, Alexander (Sandy) Wingate b. 23 March 1919 Dore & Totley, Frances Hannah b. 1 April 1920 at Sheffield and Margaret Jane Valentine b. 23 October 1921.

After Robin's birth, since America had not yet declared hostilities with Germany in the First World War, they decided they should return to England and offer service for King and Country. They sailed on S.S. Orduna from New York. (The compiler saw her in Liverpool about 1935 and found her to be in the same convoy outward for the Middle East in January 1943. Her steering gear was by then unreliable. She was involved in one night-time glancing collision and had to be left behind on several occasions to catch up as best she could.)

Possibly by the good offices of a school-day contemporary, a member of the influential marine engineering Weir family of Glasgow, Robert was rescued from the 'spud peeling' existence of a recruit in the Royal Flying Corps to be commissioned 2nd Lieutenant 15 February 1917. This Temporary Commission was transferred to that of the Royal Air Force on its formation and dated 1 December 1918.

They had found rented accommodation in Hampstead, where his widowed mother then resided at 9 Frognal Mansions. He was posted to a department of the Ministry of Supply involved with the procurement of radial engines for fighter planes, then required in ever-increasing quantities. One supplier of fighter aircraft alone, the Sopwith Company, had produced 21,000 by December 1918. Making due allowance for increasing production capacity one may safely project their annual rates as:

| Year | Qty. |

| 1915 | 1000 |

| 1916 | 3000 |

| 1917 | 7000 |

| 1918 | 10000 |

The total demand for aero-engines must have been many times in excess of these figures, and co-incidental with his commissioning the steel makers Brown Bayleys in Sheffield, had resolved their problems of producing alloy steels and were supplying forgings to the makers of their crankshafts. It so happened that the head of the department, Major R E Mainprice, was returning on demobilisation early in 1919 as Export Manager of Brown Bayleys. He was aware that there was a vacancy for the position of Works Manager, from which the co-discoverer of stainless steels, Mr Harry Brearley, wished to be released so as to pursue the metallurgical aspects.

So began his association with the company which he served until early 1937. During that time there was an extensive reinvestment in the manufacturing facilities as the markets for their products changed. He was involved with the overseeing of a variety of major contracts, including the manufacture of the forgings and machining of the two great girdle chains to encircle St. Paul's Cathedral (1930 and 1931) and later the stainless bands to strengthen the dome of the Church of the Holy Sepulchre in Jerusalem (1933). The basic manufacture of the company continued to be that of tyres for rolling stock and ever more sophisticated steels in billet form for steel product manufacturers. He had perforce much to learn of metallurgy and the steel making processes as well as the management of the plant and workforce. Every aspect was new to him and the abruptness of the Yorkshire people he would be encountering for the first time, yet by 1927 he was awarded a prize for a paper delivered in Heat Treatment. He visited Germany around 1934 in connection with the licence agreement from Krupps they held for the manufacture of austenitic steels and in 1935 visited several plants in America.

However it was a way of life with which he was never completely in tune. The workforce were obliged to take a cut in their rates of pay as the recession and hard times of the early 1930s gripped the country. He felt bound to make a proportionate gesture, which was not supported by the remainder of the management team and Directors, and not being of a clubbable nature would have tended to isolate him. He always had a high regard for Harry Brearley, a self-taught man and co-discoverer of stainless steel who had contributed much to its development.

On demobilisation, rented accommodation had been found at Dore and Totley, close to Sheffield, but shortly "Elmwood" in New Whittington, near Chesterfield, a stone-built house of the Queen Anne period, became the family home. It was set behind a high stone wall with adjacent paddock and out-buildings in which eventually a donkey was stabled. Named Bunty, she had been purchased from the rag and bone man being thought suitable when equipped with purpose-made panniers as a conveyance for the compiler astride and younger sisters on either side. A brick was an appropriate ballast for Jane the younger sister. Leather shoes were made to cover her hooves when employed to pull a heavy garden roller on the lawn.

Nursing help came and went to assist my mother with the youngest four of the family and Lizzie the cook presided in the kitchen. The imminent need of repair to the stone slab roof in 1926 coincided with a decision to send the compiler, Frances and Jane, in the care of a Miss Bielby, to Brixham to convalesce from whooping cough. "Elmwood" was sold and whilst a new house "Riggots" was building at Walton on the other side of Chesterfield, "St. Columba" was rented.

The installation of further electric furnaces around 1936 brought him in touch with the Electric Furnace Company who were supplying the equipment. They were closely linked with and maybe owned by the consulting partnership Campbell and Gifford, with offices in Victoria Street, London. They were already involved with several contracts placed by the Ministry of Supply to increase the country's manufacturing capacity of armaments, especially the improvement of many existing foundries in private ownership, the majority lacking investment and of indifferent technological skills, such as Marshalls of Gainsborough still building old-fashioned portable steam engines for the agricultural market.

He accepted their offer to take charge of this aspect of their work, and early in 1937 resigned from Brown Bayleys. The house at Walton was sold and a flat found in Maida Vale, London. Early after the outbreak of war in 1939 Victoria Street was bombed and the offices made untenable. The Partnership offices were moved to Weybridge, and leaving Maida Vale first a small flat was found in Walton on Thames and later a modest house7 in Weybridge. By that time the family were generally dispersed. From there, his work obliged him to travel extensively around the country to oversee the progress and or modification of such factories, perforce by over-crowded and unheated trains with few catering facilities.

The strain began to tell and late in 1944 he suffered a minor stroke, and never returned to his office. There were many problems of shortage and privation as the War ended, and great difficulty in finding houses. A fair sized Dutch working canal boat was then home for a while in Hamble, later giving way to a cottage at Birdham, and finally to "Elm Lodge", Apuldram Lane, Fishbourne, both near Chichester, where he died in January 1952.

| 1: | Glasgow |

| 2: | More probably 19111, 2 |

| 3: | Seattle Construction and Drydock Company |

| 4: | These were indeed produced by Washington Iron Works, but not by Seattle Construction and Drydock Company for whom he worked. |

| 5: | Seattle |

| 6: | 27 October |

| 7: | 169 Oatlands Drive |

Robert's apprenticeship – Sandy's account

Let us recollect what Sandy said above:

"Robert [became] a student apprentice in the Denny shipyard where he served through all the departments (as opposed to a trade apprentice), studying in the evenings at the Glasgow Technical College, later to become the University of Strathclyde, to gain his Diploma in Naval Architecture. By preference he wished to be involved with yacht design, but opportunities in general were at a low ebb, and so he decided to emigrate to America around 1908."

The College was officially called the Glasgow and West of Scotland Technical College, the full grandeur of whose antecedents and subsequent evolution is most authoritatively captured in this pictorial chart reproduced from the University of Strathclyde archives:

I found the Wikipedia article to be rather confusing in comparison.

I am currently [Feb 2013] trying to gather details about the commencement and completion of his course, in order to pin down the time line of his apprenticeship at Dennys. They were renowned for their technological innovations, which would doubtless have combined well with his studies. Thereafter, his inclination towards yacht design would certainly tally with a possibility of his employment (but not apprenticeship) with A and J Inglis at around 1905, as in William's account below.

Robert's apprenticeship – William's account

A letter (undated, but probably mid 1970s) from my father Walter (aka William) provides a version of Robert's apprenticeship not necessarily at variance with Sandy's narrative given above, but possibly complementary to it. As it's not terribly long I'll quote it here in full (but click here to see the original manuscript copy):

"... Have just remembered the name of the place that GrandPa Robert served his apprenticeship at: A & J Inglis Ltd ..., now long since taken over.

They were only smallish & specialised in largeish steam yachts, including one, the Mufidiyyieh, for the Khedive of [Egypt], which to allow for His Serene Highness' lack of faith in the heretical screw propeller, was installed with two-cylinder oscillating paddle wheel engines of 5000 HP each cylinder ...

Owing to the exalted position occupied by the sacred person of the Khedive in the Muslim hierarchy, the vessel's hull had to be consecrated from the outset, & guards posted on the dockyard gangway had instructions to cut first & ask questions afterwards. Your GrandPa having been a boy in Mohammedan Java, was able to recite the muezzin's call to prayer each time he passed on & off, & had free access throughout ...

After leaving Inglis he joined the Naval Design side at Fairfields ... and worked on most of the ship designs that later fought at Jutland, including the Dreadnoughts, the nuclear deterrents of their day. All got green moss on now, seven feet thick!"

Wikipedia has a somewhat different take on the historical and technical details of the Khedive's yacht, but it doesn't undermine the more colourful aspects of William's story, which clearly refers to the 1905 rebuild in which the paddle wheels were replaced by triple screws driven by newfangled steam turbines:

El Horria (originally called Mahroussa) was a Royal Yacht built for Isma'il Pasha, the Khedive of Egypt in 1865.

It was built by the Samuda Brothers on the River Thames and designed along the same lines as HMY Victoria and Albert II, and remained in service with the Egyptian royal family until 1951.

It had two significant alterations, being lengthened by 40 feet in 1872, with a further 16.5 feet being added in 1905. The 1905 rebuild was undertaken at the Pointhouse Shipyard of A & J Inglis in Glasgow, Scotland and included the replacement of its two paddle wheels with triple screws powered by steam turbines built by Inglis at their Warroch Street Engine Works in Glasgow. Inglis were one of the first companies to be granted a license by the Parsons Marine Steam Turbine Company, Wallsend for the construction of steam turbines in their own works.

And I'm not at all sure about Robert working on Dreadnought design. Admittedly the design of the eponymous HMS Dreadnought was begun in Jan 1905, her keel was laid on 2 Oct 1905, she was launched on 10 Feb 1906, and she was completed on 3 Oct 1906 – an impressive demonstration of British industrial might. But this certainly wasn't done by Fairfields, but at Portsmouth Dockyard. And the list of battleships or battlecruisers built at Fairfields includes only two such, HMS Indomitable, launched on 16 Mar 1907, and HMS New Zealand, launched on 11 Jul 1911, that Robert could possibly have been involved in.

William's account makes no mention of the Denny shipyard, nor of the evening classes at the Glasgow & West of Scotland Technical College at which Robert qualified for his Diploma in Naval Architecture.

Robert's Apprenticeship – My Version

A cherry-picking reconciliation of these two accounts is not too difficult:

- Whilst taking evening classes at GWSTC, Robert was apprenticed at Dennys shipyard.

- After completion of his course, and his apprenticeship, he moved on first to A & J Inglis and then to Fairfields.

- And then, he emigrated to the USA.

And corroboration of this, consistent with the date at which the Khedive's yacht was refitted, has just been obtained thanks to Dr Anne Cameron of the University of Strathclyde, who has very kindly transcribed Robert's original course records from 1901 to 1905, including a careers record card indicating that he went on to Inglis and Fairfields, and subsequently relocated to Seattle.

The Oral Tradition Unravels (Part 1)

Recall Sandy's innocuous statement, probably based retrospectively on first-hand conversations with his father years later (no guarantee of veridicality):

"By preference he wished to be involved with yacht design, but opportunities in general were at a low ebb, and so he decided to emigrate to America around 1908."

At the time he put that to paper it would have been a Herculean task to check the Passenger Lists of all passenger liners, of both UK and US shipping companies, leaving the various principal ports (Glasgow, Liverpool and Southampton) of Britain for America, over a period of time encompassing the date of 1908.

But these Passenger Lists have now been digitised, and by computer-generated matching procedures the lists can be searched against a set of criteria relevant to the person you're looking for. Seemples!

There are two individuals by the name of Robert Waddell, categorised as Engineer, and with approximately the right age, both starting from Glasgow, both heading for New York. One was in late 1906 (possibly him, but the details supplied on the US Passenger List are drastically different), the other in mid 1911 (definitely him, from the corroborative details supplied on the US Passenger List).

| Age | Journey Details | Date | Panel | List |

| 23 | dep Glasgow to New York | 15 Dec 1906 | link | link |

| arr New York from Glasgow | 24 Dec 1906 | link | ||

| 27 | dep Glasgow to New York | 25 Jun 1911 | link | link |

| arr New York from Glasgow | 2 Jul 1911 | link |

The first departure date (Dec 1906), with the internal evidence against it, also allows scarcely eighteen months for Robert to have worked for both A & J Inglis and Fairfields in the interim after graduating, but it's not totally implausible and is after all only just over a year before the date of departure given by Sandy.

The second departure date (Jun 1911) is at total variance with Sandy's narrative of all the things Robert had done before Hannah went out to join him.

There is however a dramatic possibility that we are still missing a trip back to the UK earlier in 1911 to reassure Hannah of his total bona fides and to placate her anxious family (who would surely have been very negative about allowing her to make that arduous and dangerous journey from Glasgow to Seattle entirely on her own). If anybody can find authentic details of "Robert's missing trip" I would be absolutely delighted.

The Oral Tradition Unravels (Part 2)

This was in the days before transatlantic telephony, emails, or internet form-filling, and the job prospects might have been very hard to assess in advance. So we can accept that he did set off to America without any clear foreknowledge of what opportunities might await him. And that there was nothing doing on the East Coast, so off he then went to the West Coast. But after that it seems to have got garbled.

First of all, the Washington Iron Company and its disparate manufacturing portfolio of logging winches and warships (strange bedfellows) just doesn't compute. There was indeed a Washington Iron Works, that flourished between 1882 and 1986, but all they made was sledge-mounted logging winches which they successfully exported to Australia.

And consultation of the extraordinarily apposite website

en.wikipedia.org/wiki/Category:Defunct_shipbuilding_companies_of_the_United_States

effectively reveals that there was never a US shipbuilder called the Washington Iron Company.

What seems much more plausible was the Seattle Construction and Drydock Company.

(This has now been corroborated by a fine piece of reportage from my cousin Samuel Waddell, which also reveals that Robert did in fact have a pre-arranged job awaiting him on the East Coast.)

It originated in a simple repair yard back in 1882, but became fully functional in 1911, was hugely successful in the construction of naval warships of every kind – from submarines to battleships – and then declined in 1918 as its workforce deserted it for bigger paypackets at other shipyards.

As the Wikipedia SCDC article relates, their speed trials were carried out in the Straits of Fuca, which ties-in exactly with Sandy's statement that the measured mile of Robert's employers lay [in the Strait of Juan de Fuca] just to the south of [the Canadian Naval Base at] Esquima(u)lt on the western perimeter of Victoria BC on Vancouver Island.

The Oral Tradition Unravels (Part 3)

Amidst the swirl of myth, rumour and speculation, there is one very telling item of documentation – two consecutive pages (p1 and p2) of the 1911 Census, conducted on 2 April 1911, relating to the household of Margaret Waddell, James' relict, and her grown-up family. That family comprised Robert (described as an engineer working in Partick), Mary (Mollie) and Margaret (Meg). Partick is just across the river Clyde from Govan, where the Fairfields shipyard was located. It therefore seems inescapable that he had stayed with them for quite some time, as William's memoir also implies, and that the journey commencing 25 Jun 1911 was his first trip to America after all.

But in that case, as reasoned above, he must have gone on more or less straight away to Seattle, which is at variance with Sandy's account. Perhaps Sandy had simply been misled as to the timeline of events – he would certainly not have dreamed them up himself.

The Oral Tradition Unravels (Part 4)

Another family tradition, recounted by my Aunt Jane, Sandy's younger sister, is that the decisive factor in Robert's decision in 1916 to quit his job in Seattle and return forthwith to the UK, was his alleged discovery that his employers were building warships nominally for the US Navy, but that these vessels were actually destined for a South American nation (named as Brazil), who were then selling them to Germany who were at that time, as any fule kno, locked in mortal combat with Britain and France.

It's perfectly true that many Americans of German and Irish origins would naturally have been rooting for Germany (and her allies) rather than for Britain (and her allies), but I've googled around a bit and find the theory unconvincing, in that the nascent Brazilian Navy bought its warships from Britain instead.

What I have found in very partial vindication of the tradition is an absolutely extraordinary tale, The Tale of Two Tubs in fact, in which his employers actually sold a pair of submarines (originally destined for Chile) to Canada (for defence against the powerful German Pacific Fleet), in contravention of America's strict non-belligerent status at that time. But these subs turned out to be rather Mickey Mouse substandard affairs, which might just have started to persuade Robert that the Mother Country's interests would best be served by his return to Britain. Or maybe he was disgusted by the huge commission to the SCDC chief executive Paterson for his Machiavellian involvement in the deception, plus the vastly inflated price Canada had to pay for two vessels that Chile had already declared to be inadequately engineered.

But on the other hand, everybody in Britain was saying that the war would be over by Christmas (1914), so perhaps returning all the way home again would be rather a pointless gesture.

Back to Blighty

But by the spring of 1916 it had become clear that the war (on the Western Front) had degenerated into a stalemate that Britain and France couldn't hope to resolve on their own. And the German U-boat campaign was starving Britain of food and raw materials. What had happened to that long golden afternoon of the Edwardian era?

So Robert and Hannah may then have resolved to abandon their new life and return to the old one, to do what they could on the Home Front.

But then Hannah realised that she was expecting their second child. My Aunt Jane has remarked that Hannah always suffered dreadfully during pregnancy, and so they decided to wait until their second child – Robin – had safely arrived. Walter – the elder son, aged 3½ at the time – once recollected that the journey was a nightmare, as Robin cried all the way across first America and then the Atlantic. Injudiciously, or maybe it was their only option at the time, they sailed on the Orduna, a Cunard vessel, flying the Red Ensign and therefore at risk every moment of the day from a U-boat torpedo attack.

| Journey Details | Date | Panel | List |

| arr Liverpool from New York | 26 Dec 1916 | link | link |

By leaving America, they had sacrificed not only Robert's job, but had exchanged a peaceful and prosperous way of life for a society in crisis. 'Squiffy' Asquith had resigned barely three weeks before, and Lloyd George, as new Prime Minister, was yet to make an impact on the conduct of the war. Robert, soon after arrival, was presented with a white feather by one of the patriotic harpies who would thrust these symbols of presumed cowardice on any male passer-by not yet in uniform. Almost impossibly short-sighted, and afflicted with recurrent bouts of malaria, he was totally unsuitable for active service anyway.

As recounted above by U Sandy, Robert was immediately conscripted into the RFC (Royal Flying Corps) and commissioned as 2nd Lieutenant1, 2 on 15 Feb 1917. This carried over when the RFC was reconstituted as the RAF (Royal Air Force) on 1 Dec 1918, and it is the RAF cap badge that he is displaying in the photograph. (Incidentally, although 34 by now he still looks extraordinarily youthful, but the few photographs in later life reveal a tired and almost haggard man, prematurely aged by overwork. This photograph also reveals, I'd say, a 'lazy eye' condition that also afflicted his son Sandy).

His organisational capabilities were soon recognised and he was seconded to the Ministry of Supply, as you may read in U Sandy's excellent account above.

Brown Bayleys

The department to which he was assigned, managed by a Major R E Mainprice, dealt with the procurement of aero engines, and Robert soon became involved with the Sheffield steelmakers Brown Bayleys who were producing a newly-developed steel alloy for this purpose, and became acquainted with their legendary employee Harry Brearley.

Brearley had previously been with the steelmakers Brown Firth Research Laboratories, where he had invented a form of stainless steel, but had moved to Brown Bayleys as works manager in 1915; however, he seems to have fluctuated between Brown Bayleys and the Firth Brearley Stainless Steel Syndicate over the next half-dozen years. It's evidently an incredibly complex story the details of which don't seem to have surfaced on the internet. Sandy wisely didn't attempt to address these complexities, and I won't either.

Brown Bayleys had also been through a period of metamorphosis in mid 1918, as attested by a notice in the London Gazette. Their chief executive Robert Armitage who ran the company from the time he acquired it in 1895 until his death in 1944, was restructuring it for the challenges of peacetime.

But, the story goes, at the end of the war, and newly demobilised in early 1919, Mainprice returned to his pre-war position as Export Manager at Brown Bayleys and suggested that Robert should apply for the job as their works manager as Brearley wanted to focus on research once again. I think Robert must have phased in gradually, as he had absolutely no previous experience of steel production and was on a very steep learning curve indeed. Brearley would surely have mentored him closely, and the two men got on very well together.

In 1925 Brearley 'went emeritus', and was awarded a directorship and his own office and secretary in perpetuity – wow! So thenceforth Robert was solely in charge of all the day to day operations of the steelmill; I would think that must have been a very lonely and nerve-racking responsibility. He wasn't a genial or gregarious person at the best of times, and I believe he was known to the workforce as Owd Bloody Bob. That probably indicated a grudging respect on their part, and he retained the position unchallenged until he was head-hunted in 1937, as U Sandy's narrative relates.

Sandy touches on two particular highlights of Robert's career at Brown Bayleys that I'd like to expand upon. The celebrated chain around St Paul's Cathedral is looked at in the next section, but let's first examine the much more controversial topic – the notorious pay cut.

It was when the Great Depression of the early/mid1930's was at its worst (paradoxically, when Britain started to rearm in response to the perceived threat from Nazi Germany, business got pretty brisk again, and pay-rates picked up). The Board of Directors decided that the workforce should take a 25% cut in their pay. Harry Brearley and Robert Waddell both asserted that a proportionate cut should be levied on directorial emoluments and managerial salaries. There was no support for this from those quarters, so Harry and Robert insisted that at least their own pay should be cut.

My Aunt Jane, who was a schoolgirl at the time, recollects that this affected the household very noticeably; for example, Robert could no longer afford to run a car, and family funds were very exiguous in many other lower-profile ways as well.

Well, well, how many times has this scenario been rerun at each and every downturn of British business or business sectors since that time? There were easily a dozen crises for my various employers or the nation at large during my working life, and never once was there any genuine indication that "we were all in it together".

Even in the Second World War (not that I got out much at that time), when strict rationing was imposed on the populace, it didn't apply to restaurants and nightclubs. Revolutions are generally disastrous, and like Cronos generally devour their own offspring, but one does sometimes yearn for a new order.

The Chain(s) round St Paul's

This is almost certainly Robert's most spectacular achievement, and the one thing that people outside the family might know about even if they didn't actually know who did it. So I make no apology for displaying this picture so boldly. Originally, though, I didn't know anything about the artist or why Robert is wearing a bathing suit, but this was all explained in Aunt Jane's ensuing memoir. First, however, we must rewind over 1300 years, back to early Saxon times.

Background

The first place of worship atop Ludgate Hill in the City of London is said to have been a Roman temple dedicated to their goddess Diana. The first cathedral, however, made of wood, was founded in 604 and dedicated to St Paul by King Ethelbert of Kent. This was later rebuilt of stone but was burned down in 962 by the Vikings in one of their traditional pre-Christmas rape, pillage and shopping expeditions. The third Saxon cathedral (together with much of London itself) was destroyed by fire in 1087, and was replaced by the Normans with Old St Paul's (as we nowadays refer to it), the longest and largest cathedral in England, taking over 200 years to complete – not least because of serious damage by fire in 1135. The spire, completed in 1315, was nearly 150 metres high, the second highest in England; in 1561 it was brought down by fire, probably caused by lightning, and was never replaced.

And, as every fule kno, the rest of the building was burned down in the Great Fire of London in 1666. Not that this was altogether a disaster, as the entire edifice had fallen on very hard times, being in a state of dangerous disrepair –and disrespect by the citizenry, who used it for social, commercial and even immoral purposes. Fortunately, two of the most remarkable men of that (or indeed any other) era were to collaborate in the design and construction of the great new building that was to arise from the ashes – Sir Christopher Wren and Robert Hooke.

Probably the most authoritative, expensive and (most importantly) readable survey of St Paul's past and present that I've come across, and have browsed via excerpts on the internet, is

- St. Paul's: The Cathedral Church of London, 604-2004

edited by Derek Keene, R. Arthur Burns, Andrew Saint published by Yale University Press, 2004 (538 pages!)

I have also scanned a couple of minutely detailed architectural drawings, in cut-away format, of the modern cathedral.

- The first is in black and white, commissioned at the outset of the reparations in the 1920's. I acquired it in two separate halves, upper and lower, which have been juxtaposed into a single entity and can viewed as an html document.

- The second is in colour, retailed in poster form, which can be viewed as an html document or as a zoom-controlled pdf document (50 MB, lengthy download).

The Dome

St Paul's Cathedral as we know it today is indeed a magnificent accomplishment, but my focus here is upon the great dome, with which Robert Waddell was to be closely associated over two centuries later. To gain an immediate appreciation of the internal complexity of the Dome's architecture, please click here.

In fact, Wren had never been officially authorised to surmount the new cathedral with a dome. In a series of designs and redesigns – initiated even before the Great Fire had finally put paid to the old cathedral – he was eventually overruled by the Planning Commission, who wanted a spire, and insisted upon it. Then the monarch himself, that libidinous, wily, worldly-wise individual Charles II gave Wren a nudge and a wink – as recounted below:

(Excerpted from www.uh.edu/engines/epi190.htm)

In 1665 the current building was a 500-year-old Gothic cathedral. It'd never really been finished, and now it was falling apart.

The brilliant young architect Christopher Wren was told to rebuild the old wreck. He put a radical plan before the Cathedral Planning Commission. He'd tear the old Gothic building down and replace it. He'd cap the new building with a dome like the ones on Renaissance churches in Europe. The Commission would have none of that. Cathedrals had spires – not domes. St. Paul's would be patched, not rebuilt; and Wren would place a new spire upon it.

Wren rankled for a year. Then nature intervened. The terrible fire of London finished off the old building, and Wren was free to design a new one. The Commission still rejected his design, even though King Charles rather liked it. Finally the King gave him a loophole. He told Wren to erase the dome from his plans and draw in a steeple – any old steeple. Then the King put a phrase in Wren's contract that granted him liberty to make such variations as from time to time he should see proper.

Wren's design was topped with a hideous, out-of-proportion steeple. But it satisfied the Commission, and he went to work. It took 35 years to build the new cathedral – far longer than the collective memory of any committee. As the structure rose, Wren made a careful sequence of changes. The bogus steeple gracefully gave way to a marvel of engineering – a great dome, 110 feet across, soaring 368 feet in the air. To hold it without buttresses, Wren girdled it with a huge iron chain§ hidden by the facing stone.

That old rusted chain was finally replaced by stainless steel in 1925.

A well-told tale, though it neglects to mention that Wren, meticulous as always, had arranged that the huge iron chain should protected from corrosion by encasing it in a trough of molten lead, which when set would exclude all traces of moisture. Nice try but not ultimately successful. And 1925 was when the programme of reparations commenced, but the new stainless chain didn't actually appear until some years later …

§ The huge iron chain around the (outer) dome was not the only form of structural reinforcement – separating the outer dome from the inner dome there was also a brickbuilt cone, all the way up which were bands of stone and iron chains which held everything tight, like the metal hoops round a barrel. Opinions vary as to whether Wren also arranged for a second great iron chain around the base of the cone as well, or whether that had to await the final stage of the reparations in 1931, as described later.

Saving St Paul's Cathedral

Despite the combined genius of Robert Hooke and Christopher Wren, just two centuries passed before the cathedral was in trouble again. Structural survey in the early 1920's revealed that both the 65,000 ton dome and the eight giant pillars supporting it were in imminent danger of disintegration and total collapse.

When one reflects that Westminster Abbey, though its construction spanned exactly 500 years (commencing in 1245 and finishing in 1745 with the completion of the two great West Towers – designed by Wren's pupil Nicholas Hawksmoor), has survived to the present day without any of the problems that have plagued St Paul's, one could almost suppose that the pagan goddess Diana had put a spiteful curse on the buildings that had supplanted her temple.

Be that as it may, the problems this time were more mundane – the materials used in construction of the pillars and the dome had deteriorated over time, or perhaps had been substandard from the start (from as early as 1689, the internal rubble cores of the pillars were beginning to settle and cause splitting in the external stone cladding). Quality assurance is a modern concept, unknown to our ancestors, and rapacious corruption permeated society from top to bottom (even in the hallowed Royal Naval dockyards). Wren himself was an extraordinarily busy man, and the supervision of construction would mostly have had to be delegated. And in any case, cathedral domes were notoriously problematical. To quote from Wikipedia about the dome of St Peter's Basilica in Rome:

In the mid-18th century, cracks appeared in the dome, so four iron chains were installed between the two shells to bind it, like the rings that keep a barrel from bursting. As many as ten chains have been installed at various times, the earliest possibly planned by Michelangelo himself as a precaution, as Brunelleschi did at Florence Cathedral.

Another QA problem for Wren was the shortage of skilled labour in London following the Great Plague: top-quality builders and craftsmen were very expensive. And, in 1697, in a bid to speed progress, Parliament suspended half of Wren's salary until the completion of the cathedral in 1710. He visited the site frequently to check progress, even being hauled up to the top of the dome in a basket when well into his seventies. So, the pressure was on to get the job done as soon as possible at the least possible cost, and, inevitably, corners got cut. Surprise!

An urgent programme of reparation (as they called it) began in 1925, and progressed with huge success, as reported in (of all places) The Sydney Morning Herald in 1928. Stripping away the journalistic exuberance, the remedial work was as follows, starting of course from below-ground upwards:

- In each of the eight pillars, 200 diametrical holes were drilled (equally spaced vertically and azimuthally), and in each hole a spirally grooved stainless-steel rod (2" thick and traversing the centre of the pillar to the far side) was inserted. High-pressure liquid cement was forced into the grooves of each rod and allowed to set before moving on.

- Scores (maybe hundreds) of stainless-steels rods 4" thick were bolted into position, both horizontally and slantingly, between the outer dome and 'inner dome' (ie cone), fixing the two apart at their intended distance until Kingdom Come.

- And finally the stainless steel chain was assembled, length by length, 30 sections, each 15' long and comprising an upper and a lower bar held 1' apart by a vertical pin at either end. As described below, these pins also served to link each section to the next. The cartoonist entirely misrepresents these sections, depicting them as containing alternately three or four horizontal bars – artistic licence and totally incorrect!

Well, absolutely no reference to our hero, the dour, reticent Robert Waddell (held, not in affection, but in grudging respect by his workforce, who knew him as Wor Bloody Bob). The reason was, of course, that as full-time Works Manager of the Brown Bayleys steelworks in Sheffield he would have had to delegate day-to-day supervision of the installation of the St Paul's chain to a deputy.

Furthermore, (as is all too common in such accounts), no reference to the earlier chain, encased in lead, that had been installed by Wren, and which would of course have had to be removed before work could start on the new one. The real innovation, of course, was the use of stainless steel, invented by Harry Brearley, Robert's predecessor as Works Manager at Brown Bayleys. We can be in no doubt that Robert himself was by now at the forefront edge of stainless (ie non-corroding) steel technology, and this is the real point of a very touching memoir by his younger daughter, my Aunt Jane, now (Jul 2013) sadly deceased. Note that she gives the length of each section as 18' rather than 15', implying a total of 25 sections rather than 30. The Sheffield Archives would need to be consulted about this inconsistency.

This work was finally completed in 1930, and exactly a decade later was to vindicate the eerily prophetic final sentence of the newspaper's report:

"Nothing less than a bombardment or an earthquake will destroy the cathedral after it leaves the renovators' hands ..."

To quote from Wikipedia:

The cathedral survived despite being targeted during the Blitz – it was struck by bombs on 10 October 1940 and 17 April 1941. On 12 September 1940 a time-delayed bomb that had struck the cathedral was successfully defused and removed by a bomb disposal detachment of Royal Engineers under the command of Temporary Lieutenant Robert Davies. Had this bomb detonated, it would have totally destroyed the cathedral, as it left a 100-foot (30 m) crater when later remotely detonated in a secure location. As a result of this action, Davies and Sapper George Cameron Wylie were both awarded the George Cross.

On 29 December 1940, the cathedral had another close call when an incendiary bomb became lodged in the lead shell of the dome but fell outwards onto the Stone Gallery and was put out before it could ignite the dome timbers.

So perhaps St Paul's survived the bombardment through human courage and resourcefulness, but it also survived the earthquaking explosions on every side – and this was most certainly due in large measure to the work of Robert Waddell in conjunction with the pioneering mathematical investigations of Robert Hooke, which I'd like to discuss a little later on.

The Adventure of the Second Chain

(with apologies to the shade of Sherlock Holmes)We must now sit up and take note of the extremely interesting reference to the St Paul's project in Uncle Sandy's biographical notes on his father's career:

Holy Moly! Two great girdling chains?

What did the avuncular Alexander mean by this? Was he simply referring to the upper and lower circlets of bars in the chain so far described? I think not, as he gives two distinct dates – 1930 and 1931. And these two circlets, plus their transverse pins, would have had to be installed at the same time, being finally complete by 1930, as he says.

In fact, there was indeed a second chain, completed in 1931, quite distinct from the first, and quite unknown to the general public, or within the family at that time, apart from Sandy and (later on) my father William. I know, because I've seen it. Twice!

The Sydney Morning Herald's report clearly states that the chain it describes was being positioned around the outside base of the outer drum, above the tops of the buttresses. In other words, in the open air.

But the second chain was positioned around the base of the brick cone that was referred to briefly in the previous section – sometimes referred to as a chimney, it supports the 650 ton lantern that sits atop the dome: one might say that the lantern is (as the police reports used to phrase such situations) without visible means of support.

How did I get to see this? Firstly, when taken by my father in the mid 1950's, and secondly when reprising the experience with a perennially adventurous friend in the mid 2000's. On that second occasion I'd contacted the Clerk of Works at St Paul's in advance, but that might not have been strictly necessary.

The chain itself was encased in concrete, possibly enclosed in a thermal jacket, and (as remarked by my friend, who was perhaps slightly underwhelmed) wasn't like seeing your girlfriend naked for the first time. As Dr Johnson said of the Giants Causeway, it was worth seeing but not worth going to see. One of the staff removed the cap from a peephole in the floor through could be seen the mosaic tiling of the nave far below – a dizzying view.

I wish now that I had been aware of all the historical issues (especially at the second visit), and so been able to gain more from the experience by asking questions as to just what Wren had done originally and how much Brown Bayleys had done to restrengthen this feature in 1931. On neither occasion did the cathedral staff mention the outer chain, which anyway would have been concealed behind stone cladding.

Perhaps it would be worth a third visit, or perhaps the Sheffield Archives could provide a more authorative and unequivocal account of the work done by Brown Bayleys.

Catenary Questions

St Paul's is unique amongst cathedrals in that it was designed and constructed entirely within the lifespan of a single architect, and in the pioneering mathematical insights – and experimentation – utilised in its design.

All too often nowadays (at least in my own inglorious career in the IT Dept of a well-known engineering multinational) one encounters process engineers who are unaware of the four laws of thermodynamics and civil engineers unaware of the six conditions of static equilibrium, and so on. Take away their design software and they'd be helpless. (All right, take away electricity and we'd all be helpless, but that's too scary to contemplate.)

For millennia, civil engineering relied on simple rules of thumb – starting with the ancient Egyptian '345 rule' for marking out a right angle, progressing to the Archimedian law of levers (ie rotational equilibrium), and the Roman invention of the arch, and then nothing for over a thousand years. The Masonic brotherhoods preserved certain secret fudge factors but these were purely empirical and didn't always work – as for example with Beauvais cathedral.

And then came Robert Hooke, a polymath and experimental genius – not in the first rank of mathematicians, admittedly, but a man of immense physical insight.

The imperative of modern science is 'Publish or Perish', as continued funding of research, and continued progress up the career ladder, depends on getting ones work into the public arena by publication in a printed or online journal. But the seventeenth century, there was much less pressure of this kind, and indeed there was sometimes a reluctance to publish ones results for fear that a rival might thereby be enabled to leapfrog ones own efforts.

One solution to this was to entrust the news of your researches only to friends or disinterested intermediaries, by means of letters; this approach was adopted by Fermat, for example (who also famously scribbled one particularly notorious result in the margin of a textbook), and he frequently used the priest Mersenne as a focal point for the exchange of mathematical epistles.

Another solution, adopted by Hooke and Newton in particular, when they wanted to establish their priority of discovery without revealing the discovery itself, was to express it as an anagrammised Latin aphorism, generally sorted in ascending alphabetical order, and then publish that! This was roughly equivalent to announcing that you'd lodged a letter with your attorney, to be published in the event of your death by foul play.

Thus in 1675, Hooke went public with "… The true mathematical and mechanical form of all manner of arches for building … A problem which no architectonic writer hath ever yet attempted, much less performed … abcccddeeeeefggiiiiiiiillmmmmnnnnnooprrsssttttttuuuuuuuvx"

Or abc(3)d(2)e(5)fg(2)i(8)l(2)m(4)n(5)o(2)pr(2)s(3)t(6)u(7)vx, in more visually friendly form.

In 1705 his executor revealed the decrypted form to be Ut pendet continuum flexile, sic stabit contiguum rigidum inversum, meaning 'As hangs a flexible line, so but inverted will stand the rigid arch.'

The flexible line is to be interpreted as an idealised cable or chain, of uniform weight per unit length, supported at each end (though the two ends need not be at the same level). As the Latin for chain is catena, such a curve is called a catenary. And so the ideal arch must be an inverted catenary.

And since a dome is simply an arch rotated by 180° about its vertical axis of symmetry, this law can be generalised to say that every vertical cross-section of an ideal dome is an inverted catenary. And now we begin to understand what connection this has with the design of a domed cathedral.

But how did Hooke arrive at his insight? After all, the shape of a hanging chain can vary very widely – depending primarily on the length of chain in comparison with the lateral distance between the endpoints of suspension. If the chain is very much longer than the gap, the two arms of the chain appear to be hanging almost vertically. And if the chain is only just as long as the gap is wide, it appears to be stretched almost horizontally.

(The latter case was unintentionally versified in a dictum by William Whewell: No force on earth however great / can stretch a cord however fine / into a horizontal line / that will be accurately straight / There will always be some dipping down.)

But what is common to all cases is that the weight of each tiny section of chain is counteracted by the very slight difference between the upward tension provided by the tiny section just above it, and the downward tension provided by the tiny section just below it, while the sideways tension exerted by the tiny section just above it is exactly cancelled by the opposing sideways tension of the tiny section just below it.

This sideways cancellation must occur, otherwise the tiny section in the middle would be subjected to a lateral force, thereby destroying the self-evident equilibrium.

This purely verbal analysis can be confirmed mathematically. Meanwhile we can follow-through on Hooke's chain of thought (or thought of chain): if an arch were to be built in the shape of an inverted catenary, so that instead of opposing tensions we were now considering opposing reactions from each side of a typical section of arch, the lateral forces would again cancel out - there would be no sideways thrust at any point in the structure. In other structures such thrusts do exist, and have to be countered by the use of mortar, but in principle a catenary arch (or dome) could be successfully built without the use of mortar – even in the absence of natural friction between the building blocks!

Any natural ground-tremor or nearby explosion will inevitably shake an entire domed building, damaging the mortar, and unleashing the lateral forces in a conventionally-constructed dome that the damaged mortar can no longer contain. Serious damage is therefore inevitable to the dome – and if it collapses, then to the rest of the building too.

But if the dome is constructed in catenary form, there are no lateral forces to unleash, and damage to the dome – and the building itself – will be minimal. This is the third of the three reasons why St Paul's Cathedral survived the Luftwaffe's onslaught so successfully during the Blitz of 1940/41.

Speaking as the bald-headed man at the back of the omnibus, I'm not at all convinced that the dome, on which construction started in 1703, was actually profiled to a truly (inverted) catenary shape.

The best algebraism that Hooke produced was the preposterously-named 'cubico-paraboloid conoid'. What did this mean? In essence, a cubic of revolution, such as would result from rotating the curve y = x3 about the upper y-axis (and then inverting). As the delightful Ms Jardine remarks on p 333 op cit, "Hooke was never above a bit of bluffing when the theoretical details ... eluded him." Me too. But by dint of diligent model-making and up-scaling, the builders of the dome did incontestably produce a very fair emulation of the true catenary shape.

Hooke's predilection for overstating his mathematical abilities had some less pardonable consequences, in that Newton (in his Principia) deliberately used immensely complicated geometrical arguments to prove Kepler's three laws of elliptical planetary motion from an inverse-square law of gravity. In the special case of circular motion it's probably quite true that Hooke could reproduce the two remaining laws, and may even have anticipated Newton in this respect, but the general case was beyond his powers. And so, as Newton avowed, "To avoid being baited by little smatterers in mathematics, I designedly made the Principia abstract; but yet as to be understood by able mathematicians ...".

He probably also had Leibniz in mind as well! But his eschewal of calculus in the Principia is said by many historians of science to have delayed the progress of English mathematical physics by a century. Today of course, the application of calculus and coordinate geometry to prove Kepler's laws is well within the grasp of a reasonably diligent A-level student.

One very last issue still bothers me, but then I really must crack on with other stuff. The Dome of St Paul's comprises three parts: outer dome, middle dome (chimney), inner dome. The sources hitherto available to me are all remarkably contradictory, or merely coy, as to which of these is catenoid as built, and not just conceptually in various stages of the design process.

But with one last throw of the Google bones, a surely most authoritative source (written by a distinguished academic at the University of Yale) has materialised, its Table of Contents conjugating all sorts of fascinating topics:

George L Hersey, Architecture and Geometry in the Age of the Baroque1, 2, University of Chicago Press, 2000

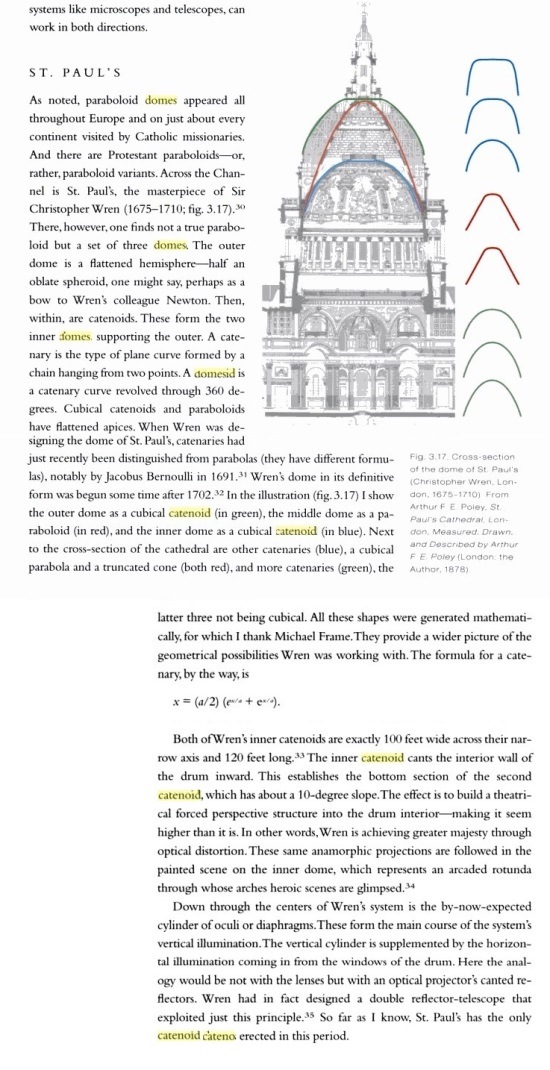

This will spill the beans once and for all ... surely? Let's see pp 69–70, slightly obscured by the kindly publisher:

- Hersey says firstly, quite unequivocally, that the outer dome is actually a flattened hemisphere, and that the two inner domes are conicoids.

- Then he suggests that the outer dome is a cubical catenoid, the middle dome is a cubical paraboloid, and the inner dome is a cubical catenoid.

- He finally relents by describing the middle and inner domes as catenoids.

He doesn't explain the meanings or algebra of conicoids, cubical paraboloids or cubical catenoids, and I feel more confused rather than less, except insofar as Hersey has sort of confirmed that it was on the middle and inner domes that Hooke and Wren focussed their efforts to simulate the catenary profile.

All the domes or turret-tops conceivable in contexts of this sort are simply surfaces of revolution generated by rotating a suitable algebraic profile (generatrix) through 180° about its central axis (or by 360° in the conical case).

| Dome | Generatrix |

| Cone | Slanted line |

| Hemisphere | Upper semi-circle |

| Flattened hemisphere (1) | Upper semi-ellipse |

| Flattened hemisphere (2) | Upper semi-superellipse |

| Paraboloid | Inverted parabola |

| Catenoid | Inverted catenary |

Like Socrates' victims, one reaches a stage of aporia, neither knowing (nor indeed caring) how one ought to proceed.

Switching, therefore, to a more practical aspect, how would the excellent artisans of those days have gone about the task of realising such a surface in the reality of timber, brick and stone? Let's take the cone as our paradigm, with height h and base-radius c. At any particular radius r from the central axis of the dome, quite independent of azimuthal angle ϕ, the downward-sloping surface has a height z = ar +b. The parameters a and b succumb to the fixed-point requirements (r=0, z=h) and (r=c, z=0) and so the generatrix has the form z = h(1 – r/c). Seemples!

Saving the Church of the Holy Sepulchre

Also commanding our attention, in view of the pivotal significance of the Church of the Holy Sepulchre in the history of Christianity – not that this would have cut much ice with Robert – is the work, carried out under his direction, on strengthening and stabilising the dome of this ancient church, as mentioned by Sandy

and also by that august but sadly defunct organ quoted below. It's really rather odd that we have had to turn to newspapers in Australia and Singapore to retrieve contemporary accounts of Brown Bayley's architectural triumphs in London and Palestine.

Letters from America

In early 1935, as Works Manager of Brown Bayleys, Robert Waddell headed to America, on a pre-arranged itinerary, to visit a number of big American steel manufacturers and customers, on a mission that combined business, fact-finding and charm offensive, on behalf of his Board of Directors.

As we shall see, however, the visit also seems to have exposed some fault-lines in his marriage. Well, what marriage doesn't have plenty of those? Mine has not a few, as the Supreme Domestic Entity would readily confirm. More importantly, for present purposes, it also revealed a good deal – through his letters home – about Robert himself, who in my opinion was the most interesting and talented Waddell of an earlier generation ever to draw breath (though my brother Simon and cousin James would run him close).

Please click as appropriate on the options displayed below. Bear in mind that Alcock & Brown had only recently (15 Jun 1919) crossed the Atlantic by air, so that intercontinental letters still took at the very least a week by sea.

And the incidental hazards of ferocious weather and nauseating seasickness, plus the significant possibility of shipwreck and drowning, would be very unnerving to a modern generation. Just over two decades earlier, Robert's then fiancée Hannah had crossed the Atlantic to New York only a few weeks before the Titanic disaster of 15 Apr 1912. And Robert's outward journey, which he describes graphically, sounds absolutely terrifying.

Interestingly, Robert travelled both in both directions aboard the Cunard & White Star flagship RMS Majestic, then the largest ship afloat. But paradoxically, she was of German rather than British construction, and had been launched as Bismarck in 1914 by that notorious one-armed bandit Kaiser Wilhelm II, but had subsequently been handed over to Britain in 1922 as part of the German reparations for the First World War.

| # | Date of letter | Image | Transcription |

| 0 | 21 Feb 1935 | √ | √ |

| 1 | 24 Feb 1935 | √ | √ |

| 2 | 2 Mar 1935 | √ | √ |

| 3 | 6 Mar 1935 | √ | √ |

| 4 | 9 Mar 1935 | √ | √ |

| 5 | 28 Mar 1935 | √ | √ |

| 6 | 2 Apr 1935 | √ | √ |

In many respects, this trip represented the high point in his career. At some point in the next two years his position at Brown Bayleys was made untenable when (according to Aunt Jane) the Board of Directors appointed a relatively inexperienced member of the Armitage family to a position which seriously encroached on Robert's responsibilities, and he resigned from Brown Bayleys in early 1937 – Jane well remembered cycling over to Farnley Hall with her father, who was determined to dissuade Robert Armitage from this folly (not for Robert W's own benefit but for that of the Company – Robert W himself was easily able to find congenial new employment.)

But the following year his second son, the Baldur of the family, my namesake, died unexpectedly and horribly, and the year afterwards, the war that followed the War To End All Wars began, in which Robert's new responsibilities were so arduous that his health declined irrevocably. His race was run, and I am the last remembrancer of how capably and honourably he ran it.

Variable Later

This legendary phrase from the BBC Shipping Forecast perfectly describes Robert's career from early 1937 onwards. Uncle Sandy's narrative has it that he was headhunted in that year by Campbell and Gifford, the engineering consultancy with whom he had had dealings as Works Manager at Brown Bayleys. Aunt Jane was of the opinion that there had been a boardroom reshuffle and that Hugh Armitage, a member of the proprietorial family dynasty, had either replaced or sidelined Robert. Either way, Robert left Brown Bayleys and joined Campbell and Gifford's offices at Victoria Street in London.

As Harley Street for medical consultants and Wimpole Street for high-class dentists, Victoria Street was for engineering consultancies. In my own secondary-school days, I used to marvel at all the burnished brass company nameplates as I walked to and fro between Victoria Station and Palace Street – the one that always particularly caught my eye was the Activated Sludge Co., subject of the celebrated humorous essay by Paul Jennings in his anthology Oddly Enough.

And so the family moved south – though the eldest son Walter had flown the nest years previously, and the next eldest, Robin, remained in the Chesterfield area. A flat was found in Maida Vale, or possibly in Kilburn (although the two areas, W9 and NW6 respectively, are in fact contiguous, as can be seen from a map of the London district codes, Victoria being located in SW1). Then, as Sandy narrates, the Luftwaffe arrived and the offices moved out of further harm's way to Weybridge. The household duly followed, first to a flat in Walton-on-Thames and then to a house in Weybridge itself, located close by, in a quiet corner of Surrey to the southwest of London.

Aunt Jane once remarked quite matter-of-factly of his secretary at that time, Binkie Biggs, that "she was his girl-friend, you know, but it was all perfectly innocent, of course, there wasn't any s*x involved". This was rather startling on several levels, not least because it was the only time I had ever heard any of my older relatives use that particular word. Regardless of any deeper implications, it probably did his morale a world of good. As a sulky teenager I was once sent to stay with her in Weybridge for a weekend, though without a clue as to who she was, and she was indeed rather nice, and very fond of music – which had probably been the principal bond between them.

At some point during the war, according to Aunt Jane, Robert transferred to, or at least was seconded to, the Alan Good organisation. For it was there, she said, that he was visited one day by his elder son Walter in some engineering capacity – they weren't at all close in a family context – and it was during this visit that Walter encountered one of Alan Good's secretaries: a young woman by the name of Kathleen Blunt. This was in about 1942 and in 1944 they were married and in 1945 I arrived, followed four years later by my brother Simon. But Robert was to see little if any of this – his health, always fragile, was increasingly undermined by the incessant travelling involved in overseeing military engineering procurements, and in 1944 he suffered his first stroke. His career was effectively over.

But still he kept on moving house. And it was Hannah who had to organise the planning and logistics of each relocation, the packing up, the removal vans, the unpacking, the redeployment of furniture etc etc. Aunt Jane very much admired her mother's quiet efficiency and the speed at which the new household would be fully up and running within a day or two of arrival. Great Aunt Val, on the other hand, found particular fault with Robert in that he left all these things to Hannah (her sister), whose own constitution was never robust.

The next move was, as Sandy says, to a large Dutch barge, moored on the River Hamble, on the eastern side of Southampton Water. My father once mentioned that Robert had wanted him to bring a boat over from Holland (he himself turned down the suggestion), and this must have been it. According to William, the barge had been equipped with twin diesel engines, with counter-rotating propellers, but Robert, being a purist in such matters, had had them removed, ostensibly to make more room on board. Hannah hated it, and who can blame her. Cold, damp, and cramped, with minimal cooking facilities, no hot running water once the engines were removed, and hand-pumped heads.

I think the barge was later moved to Birdham Pool, which Hannah found much more congenial socially – she became the greatest of friends with Mrs Arthur, who had a cottage facing onto the Pool. One thing led to another, Robert sold the barge and bought one of the adjacent cottages, aptly named Well Cottage, and they moved into it for a while.

Their final move was to Elm Lodge, a pleasant bungalow tucked away down Apuldram (now Appledram) Lane on the outskirts of Fishbourne, near Chichester (not Fishbourne, Isle of Wight!). It had lawns front, side and rear, a small orchard and quite a sizeable kitchen garden at the far end. Plus crab-apple trees on the front lawn, a solid silver birch at the side, and a massive walnut tree and two huge pine-trees in the back, to the tops of the three latter of which I loved climbing in the years to come.

The only downside was Robert's health. He now needed round-the-clock attention, and was tended night and day by Hannah and Frances, their elder daughter. When Sandy returned on leave from Kenya, he was horrified by the situation and engaged two nurses (day / night), whom Hannah promptly dismissed as soon as he returned to Kenya. By the time Robert died in early 1952 both she and Frances were worn to a ravelling, constitutionally and psychologically.

Grave Concerns

Robert was buried in the graveyard of Fishbourne's Church of St Peter and St Mary, just across the fields from Elm Lodge, with a headstone inscribed simply Robert Waddell, 1883 – 1952. I noticed it every time I was taken to Matins by Hannah (Grannie) or by Aunt Jane, though it was never pointed out. It was intriguing of course, the same name as myself though with no nasty "Erskine" in the middle.

In later years I looked for it again, but couldn't find it. There had been many changes in the church itself, and I wondered whether Robert's headstone had been rationalised into oblivion.

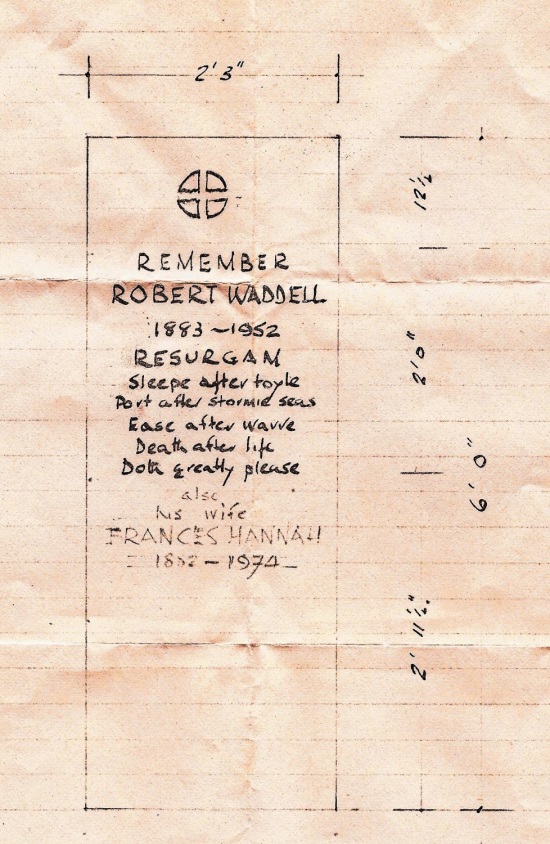

Imagine my surprise, therefore, when I recently came across a rather dog-eared photocopy of a design sketch sent to Jane by her brother Sandy during the mid 1970's. Altogether more elaborate, and with a religious optimism which surely Robert had not shared – and with a reference to Hannah!

I had always supposed that Grannie, by far the dearest person in the world to me, had been cremated – so had her ashes been buried with Robert? With a new gravestone? But of course both my parents, and my brother, had been declared non grata by the time of her funeral, and further details were off-limits to me too. In retrospect one feels bemused rather than embittered!

The photocopy responded well to autocorrection after scanning:

But the following facsimile might be easier to read:

REMEMBER

ROBERT WADDELL

1883 – 1952

RESURGAM

Sleepe after toyle

Port after stormie seas

Ease after warre

Death after life

Doth greatly please

also

his wife

FRANCES HANNAH

1882 – 1974

Robert was a very well-read man, and would most certainly have appreciated the quotation, and might also have murmured,

What if some little Pain the Passage have,

That makes frail Flesh to fear the bitter Wave?

Is not short Pain well borne, that brings long Ease,

And lays the Soul to sleep in quiet Grave?

though from a slightly later edition of Spenser's Faërie Queene (Book I, Canto IX, Stanza XLI).

And during my mother's Memorial Service in that same church 56 years later, I quoted a more prosaic soundbite from a noticeboard seen earlier that day, "God promises not a calm passage but a safe haven".

Another point of interest is that this design is no longer a headstone, but intended as a ledger stone (ie horizontal slab). And indeed I then found an actual photograph of it, though picturesquely belichened and not altogether legible, probably taken in the 1990's.

It's well overdue for a spring-clean, and hopefully this can be arranged in the not-too-distant future, when its exact location has been determined!